COUNTER PRESSURE CASTING PROCESS

LMC Technology provides consulting and technical support on:

-Aluminum alloys

-Metal treatment

-Chemical analysis

-Mold construction

-Mold cooling design

-Casting process parameters

-Casting conditions

-Quality assurance

-Sand and permanent mold casting

Counter Pressure Casting Process

What is Counter Pressure Casting Process?

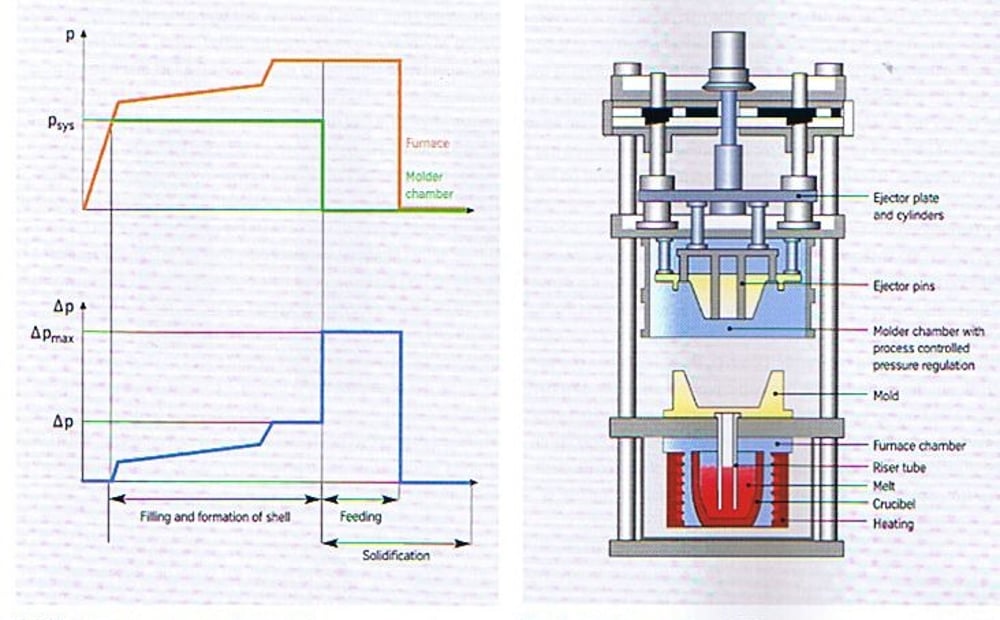

Counter Pressure Casting process uses a combination of pressure and counter pressure to control of mold filling.

During mold filling the molten metal is continuously exposed to increased pressure, which suppresses the precipitation of gases, i.e. hydrogen.

During solidification and the associated shrinkage of the metal, the pressure is maintained to prevent the formation of solidification porosity and cavities

Consulting and Technical Services

LMC Technology offers:

Optimization of the counter pressure casting procedure, which applies different types of pressure during the feeding and solidification process in order to produce lighter and stronger aluminum parts. These procedures have shown to work especially well for casting designs with varying wall thickness, particularly for steering knuckles and suspension parts in the automotive industry. Innovative casting process, with the purpose to eliminate oxides and inclusions within the castings, by modifying the filling procedure in vertical casting methods.

Variations in the Counter Pressure Casting Process

Pressure vs. Time

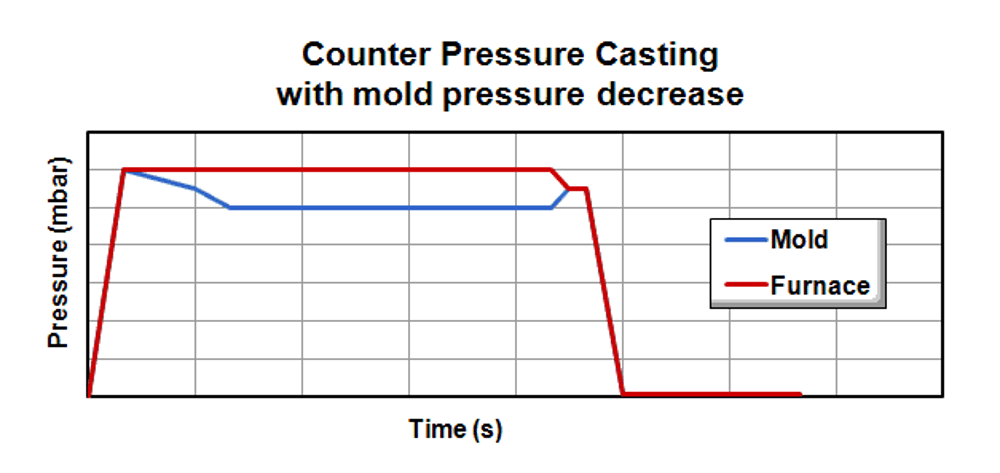

Additional variations in the Counter Pressure Casting Process

Pressure vs. Time